Laboratory equipment and instruments are essential components of laboratories, but

special precautions are needed when utilizing them for research involving biohazards.

This chapter of the Biosafety Manual will provide guidance related to the use,

care, and disinfection of common laboratory equipment and instruments.

1.

PROCEDURE:

1.1. General Procedures

- All equipment that is utilized to manipulate, transport, or store biohazards

must be identified with the universal biohazard symbol.

- For laboratories at Health Sciences Center, prior to moving between laboratories, moving to surplus, or disposing, all equipment must be decontaminated. Refer to

Chapter 8: Decontamination, Disinfection, and Spill Response for equipment.

1.2. Equipment Specific Procedures

1.2.1. AUTOCLAVE

Autoclave Use

Refer to

Chapter 5: Biohazard Waste for guidance in operation of the autoclave.

Autoclave Maintenance

Spore Test

Autoclaves used to sterilize infectious medical waste that is being disposed of in

a sanitary landfill must undergo periodic spore tests. West Virginia Infectious

Medical Waste Program requires the autoclave sterilization be evaluated using

Bacillus stearothermophilus spores every forty hours of operation. The results

of this test must be recorded in the autoclave use log.

- Place the biological indicator inside an autoclave bag and place in the tray

with a load that needs autoclaved.

- Autoclave using the appropriate validated cycle for infectious medical waste.

- Once the cycle is complete, remove the tray with bags from the autoclave using

heat-resistant gloves and eye protection.

- Let the contents cool (at least 10-15 minutes).

- CAUTION: Biological indicators are hot and under pressure when removing from

the autoclave. Failure to allow sufficient cooling time may result in the

bursting of the ampule.

- Follow the manufacturer’s instructions for incubation time, temperature, and

reading test results.

- If the autoclaved indicator turns yellow or becomes turbid, evaluate the time,

temperature, and autoclave procedures. Contact an autoclave repair company

if a problem with the autoclave is suspected. Do not use the autoclave until

the problem is fixed and a successful biological indicator test has been performed.

- Regardless of results, document the autoclave test results in the autoclave log

along with any remediation that may have occurred.

1.2.2. BIOLOGICAL SAFETY CABINET

Biological Safety Cabinets (BSCs) are one of the most common forms of primary containment

in microbiological and biomedical laboratories. BSCs are designed to provide protection

to the operator, the environment, and the product.

Class II BSCs are required for use in BSL2 laboratories, especially for any procedure

that has the potential to generate aerosols. It is recommended that all work

with BSL2 biohazards be performed in the BSC.

Common procedures that generate aerosols include, but are not limited to:

- Centrifugation

- Vortexing

- Pipetting

- Tissue Homogenization

- Opening vacutainer tubes

- Changing animal bedding

Two types of Class II BSCs exist: A2 and B2. A2 BSCs are exhausted through HEPA filtration

back into the laboratory; therefore, do not provide any protection against chemical

gases or fumes. A2 cabinets can be connected to a hard-ducted exhaust

system via a canopy (thimble). This provides protection against some minute quantities

of volatile toxic chemicals. B2 BSCs are exhausted through HEPA filtration and

then through a hard-ducted exhaust system and additionally provide protection against

chemical gases and fumes. The biosafety office can help determine which type of

BSC is appropriate for your research.

BSC Certification

BSCs are required to be tested and recertified annually by a qualified outside

vendor.

Contact the Biosafety Office for a list of qualified outside vendors. The

vendor is responsible for verifying that the BSC is functioning properly, that

the air flows are adequate for safe operation, and verify the integrity of the

HEPA filter.

BSCs must be certified prior to initial use and recertified after being moved to

a new laboratory.

Proper BSC Use

Prior to use, turn on the blower and allow the BSC to run for at least 5 minutes

to purge the air inside the cabinet. Verify that the BSC has not exceeded its recertification

date. It is best practice to disinfect the working surface of the BSC prior to

use with a suitable disinfectant.

During use, do not overfill the cabinet. Only place in the BSC in what you need for

the procedure you are performing. Ensure none of the interior air grills are blocked

or covered. Ensure the front grill of the cabinet is unobstructed; do not place

equipment, papers, or rest your arms on the grill.

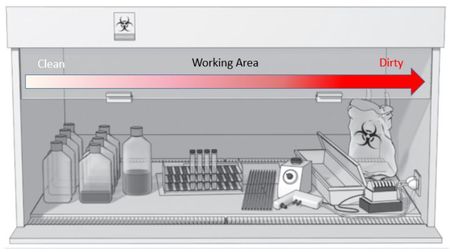

During use, the cabinet should be organized in a manner so that workflowsws from a

“clean side” to a “dirty side”. This will prevent cross contamination of your product.

Refer to Figure 1 for an example of BSC organization for a right-handed handed individual.

A left-handedhanded individual would prefer a reverse setup.

Figure 1. Example of BSC Organization

After use, disinfect all equipment prior to removing from the BSC. Lastly, disinfect

the interior surfaces of the BSC and allow the blower to run for at least 5 minutes

to purge the air inside the cabinet. Ensure a suitable disinfectant is utilized.

BSC Maintenance

- Routine maintenance of the BSC should include disinfecting all inner surfaces

and removing any debris or dust that may collect under the work area in the

lower plenum area.

- Bulbs within the BSC are required to be changed by the lab; Facilities Management

will not change bulbs.

- A qualified vendor must perform all other maintenance or repair of the unit,

including HEPA filter replacement. Gas decontamination may be required by the

vendor as part of the maintenance or repair.

Moving a BSC

Prior to moving a BSC to a different location, contact the Biosafety Office. The

BSC will need to be gas decontaminated by a qualified, outside vendor and verified

by the Biosafety office as decontaminated.

1.2.3. CENTRIFUGES

Hazards associated with centrifuges include the creation of aerosols, loss of containment,

and mechanical equipment failure. Care must be taken when centrifuging biohazards

to minimize centrifuge hazards.

Centrifuge Use

Prior to use, verify that the centrifuge is clean and that the rotor is not damaged

or has exceeded its life expectancy. To determine the life expectancy of a rotor,

check the manual or contact the manufacturer.

- During operation, use sealed test tubes.

- Avoid the use of glass test tubes when possible.

- Do not overfill the tubes.

- Ensure the load is properly balanced.

- It is highly recommended to use a

sealed, aerosol-tight rotor during centrifugation of biohazards when working

at BSL2 or higher.

- Sealed rotors, or tubes should be opened and manipulated within a BSC to reduce

the risk from aerosol production.

Centrifuge Maintenance

- Routine maintenance of a centrifuge should include disinfecting all inner surfaces

with a suitable disinfectant, including the rotor and/or buckets, and removing

any debris or dust that may collect within the unit.

- Observe the unit, including the rotor, or signs of wear or damage.

- Follow all manufacturer’s recommended guidelines for preventative maintenance

of unit.

1.2.4. COLD ROOMS

As cold rooms are usually shared among multiple labs, they create unique challenges

to ensure a clean and safe environment is maintained. Each lab that utilizes the

cold room must take responsibility in maintaining the room. Given the cold and

damp environment commonly encountered in cold rooms, mold growth is one of the

most common occupational hazards encountered.

Cold Room Use

- In order to minimize excess moisture from entering a cold room, it is imperative

to keep the cold room door firmly shut. Any spills or standing water should

be wiped dry promptly.

- Only those items that are needed should be brought in the cold room.

- Do not store non-essential items in the cold room.

- Shelving and other storage items must be made from plastic or metal.

-

Cellulose-based (cardboard, paper, wood, etc.) materials are NOT permitted

to be stored in the cold room. This is the primary cause of mold contamination

within a cold room.

If this policy is not followed, mold remediation is the responsibility of the

labs utilizing the cold room.

- Necessary paper products (kim wipes, paper towels, etc.) may be stored in the

cold room if they are stored within a closed, air-tight plastic container.

Plastic totes or tubs must be utilized in place of cardboard boxes.

Cold Room Maintenance

Cold rooms must be routinely disinfected to help maintain a mold-free environment.

Monthly surface disinfection within the cold room is recommended as best practice,

however at a minimum must be performed quarterly.

This should include all inner surfaces of the room, lab bench, chairs, storage/shelving,

and inlet and exhaust grills of the cooling blower.

An EPA registered, fungicidal disinfectant, such as Peroxigard (Rescue) is optimal,

as it will not damage metal surfaces. However, any fungicidal disinfectant is acceptable if an appropriate contact time is achieved. A 10% bleach solution is effective

to kill visible, vegetative mold, however, does not kill mold spores. Following

the use of bleach, any metal surfaces must be wiped with water to remove any bleach

residue. Bleach residue is corrosive to metal surfaces. Following disinfection,

all surfaces should be wiped dry so excess moisture does not remain in the cold

room.

CAUTION: Cold rooms typically have closed air circulation; the only source

of fresh air being when the door is open. If disinfecting with a bleach solution,

be aware that fumes will recirculate within the cold room and can cause mucus membrane

irritation even after a short period of time. The door should be proper ajar during

bleach disinfection.

Quarterly assessment of cold room inventory should be performed. During this assessment,

all expired items, items which are no longer needed within the room, and any items

with visible mold contamination must be removed or discarded.

1.2.5. FREEZERS AND REFRIGERATORS (COLD STORAGE)

Freezers and refrigerators are common pieces of equipment in laboratories for cold

storage. They present potential risks of exposure to biohazards if not properly

used or maintained. In addition to mold contamination, there is risk of exposure

to biohazards if contents are not properly stored. This section applies to laboratory

refrigerators, freezers (also referred to as -20 freezers), and Ultra Low Temperature

(ULT) freezers (also referred to as -80 freezers).

Cold Storage Use

All laboratory cold storage equipment must be marked with a “No Food or Drink” sign.

All tubes, flasks, beakers, or containers must be sealed closed with a solid lid

or cap. Parafilm alone is not an acceptable closure. All tubes, flasks, beakers,

or containers must always be stored upright within cold storage. Tubes, flasks,

beakers, or containers containing liquid solutions or suspensions of biohazards

should be closed with a lid and additionally be sealed with parafilm within cold

storage. All petri dishes containing microorganisms must be sealed with parafilm

within cold storage. Label all items with the full name of what is being stored,

along with name/initials and date of the person responsible for the item.

Biohazard and potentially biohazardous spills must be immediately decontaminated

and cleaned. Refer to

Chapter 8: Decontamination, Disinfection, and Spill Response for proper spill

response procedures.

Cold Storage Maintenance

A check of inventory within the cold storage should be routinely performed. Anything

damaged, expired, or no longer needed should be properly discarded.

At minimum, all contents of the cold storage equipment should be removed and the

inside wiped with an appropriate disinfectant once a year. Excessive frost should

be removed from any freezer.

1.2.6. IN-HOUSE VACUUM SYSTEMS

In-house vacuum systems are often used in labs that perform cell culture to remove

media from the cultures. Biohazard risk to the in-house vacuum system involves

any biohazards breaching the suction flask and being drawn into the system. To

prevent this from happening, a simple setup utilizing flask and filters can be

used (see below).

In-House Vacuum System Use

For aspirating media or other suction purposes, proper setup requires the use of

a suction flask (

B) attached to the in-house vacuum system (

D) with vacuum tubing. An in-line HEPA filter (

C) must be utilized between the suction flask and the vacuum system valve (

D). The suction flask must be properly labelled (

A) with the full name of all contents of the waste in the flask.

The in-line HEPA filter will provide protection against aerosols from entering the

in-house vacuum system, however great care must also be taken to not overfill the

suction flask.

In-House Vacuum System Maintenance

The in-line HEPA filter must be changed whenever the filter is compromised, wet,

or otherwise damaged. At minimum, the filter should be changed on an annual basis.

Writing the install date on the side of the filter will aid in proper replacement.

A readily available HEPA vent filter is the Whatman HEPA Vent Filter (Fisher cat.

# 09-744-79).

Any liquid waste collected in the suction flask must be immediately disinfected with

household bleach, to a final concentration of 10%. Refer to

Chapter 5: Biohazard Waste for additional guidance for treatment of liquid

biohazardous waste.

At the time of use, the suction flask can be pre-filled with household bleach so

that a 10% final concentration of the entire flask is obtained. For example, add

400 ml to a 4L flask, which will ensure a minimum of 10% concentration is obtained

throughout the work performed that day.

If pre-treating with bleach, it is only effective for approximately 24 hours, so

it must be disposed of each day.

1.2.7. SHARPS

Sharps include instruments or other objects that could readily puncture or lacerate

the skin. Some common examples of sharps are listed below. Whenever possible, consider

alternative methods with non-sharps equipment and instruments to minimize exposures

from needle-sticks or lacerations.

- Hypodermic syringes

- Razor blades

- Suture and other needles

- Scalpels

- Lancets and other fingerstick devices

- Broken glass

- Glass pipettes

- IV catheters

When sharps use is unavoidable, the follow precautions must be taken to help minimize

the risk of needle-stick or laceration:

- Syringes and needles must never be recapped.

- Sharps must be immediately disposed of within a sharps container upon completion

of use.

- Reusable sharps, such as dissection pins or razor blades, must be stored with

the blade or point covered, when not in use.

- It is recommended to store sharps in a block of Styrofoam.

- Sharps must not be left out on the lab bench when not in use.

- Sharps must be autoclaved in a hard-walled container and identify that sharps

are present within.

- If cutting tissue, hold the tissue with forceps or other mechanical devices;

never with your fingers.

Return to Table of Contents

Continue to

Chapter 8: Decontamination, Disinfection, and Spill Response

Version History:

|

Revision Control Table

|

|

Version

|

Changes

|

Revised by

|

|

1.0

|

Initial version

|

Matt Stinoski

|

|

2.1

|

Content added and updated

|

Matt Stinoski

|

3.0 (7/2/24)

|

Typos fixed, content updated, grammar changes

|

Josh Parenti

|